BENEATH IT ALL,

MAXXON DELIVERS

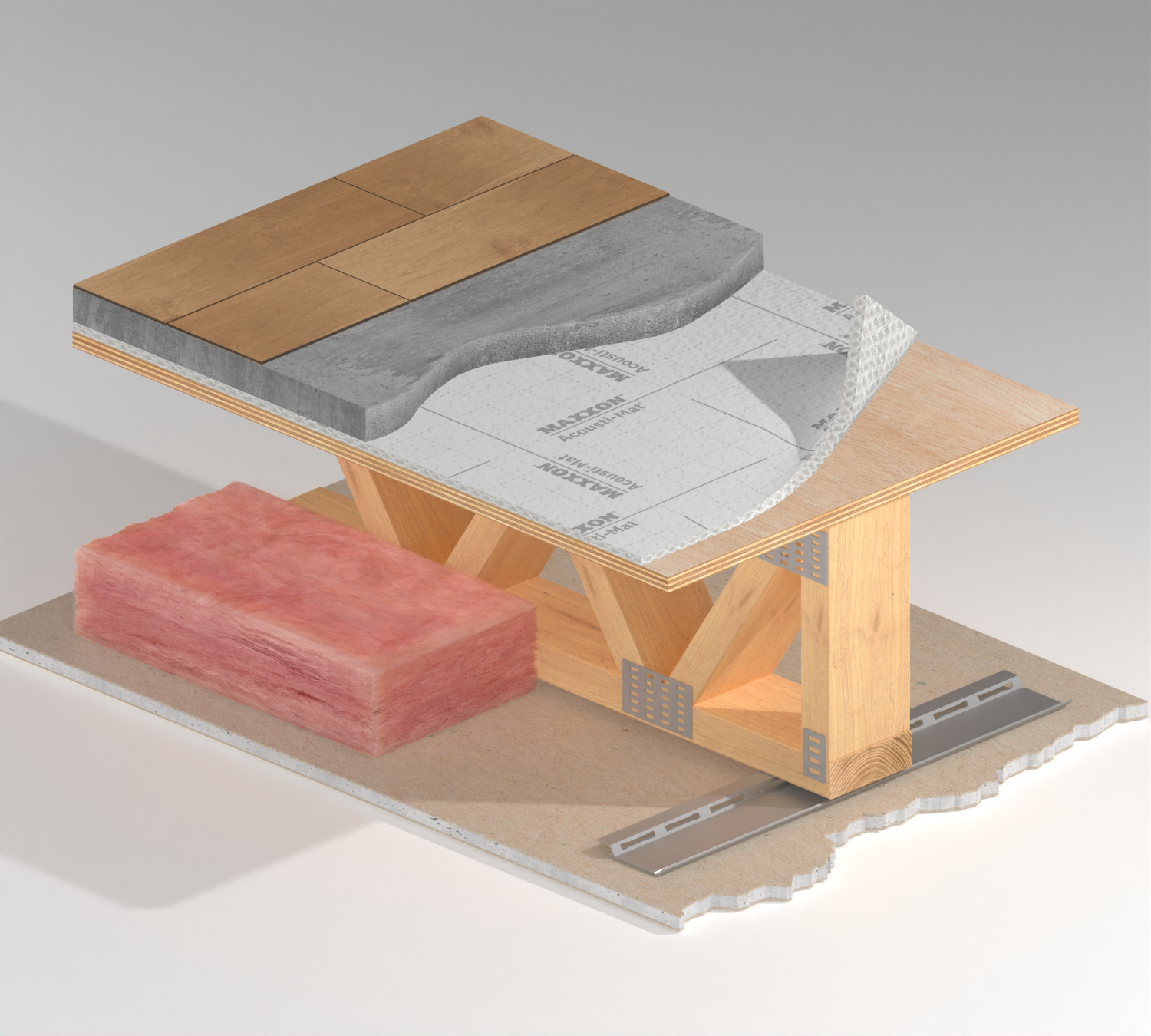

Maxxon® is the creator of the original Gyp-Crete® floor underlayment. We continue to innovate and develop new products and solutions for subfloor prep and finishing.

Why MaxxonSystem SelectorMultifamily Work

Applicator Installed

The industry standard for use over wood subfloors in multifamily construction.

Commercial Work

Applicator Installed

Underlayment installed by a Maxxon applicator professional for commercial properties.

How can we help you today?

Get Started With Maxxon

Fire & Sound Data

Download the Maxxon Fire & Sound Manual to help you determine the right system for your project.

Fire & Sound

System Selector

Not sure where to start? Try out our interactive system selctor to help you find the right solution.

Get Started

Product Installation Guide

Watch installation videos and get step-by-step instructions for all available Maxxon products.

View Installation Guides

Technical Specs

Learn more about product features, benefits, technical information, and installation instructions.

View Tech Specs

Project Gallery

We like to let our work speak for itself. Take a look at our featured projects to learn why Maxxon is the right subfloor expert for your needs.

View Projects

We're Industry Leaders and Innovators

Pioneers from day one, we developed Gyp-Crete, which has been the industry leader in underlayment for nearly 50 years. We continue to innovate new products for a better quality of living.

Maxxon products are made of the highest quality and built to perform. Not sure which product is right for you? Our knowledgeable support team can help you find the right solution for your need and will help troubleshoot any issue that may arise.

You can feel confident that Maxxon products are not only environmentally friendly, but also made in the USA.

Connect With Us

Underlayments and sound control mats are installed on the job site by authorized dealers. Find an authorized dealer in your area.

Contact Us